Every second counts in critical power infrastructure projects. When Petrozone International was called in for a high-priority RMU replacement and cable termination project, we knew this would be an intense challenge. The site, a critical operational facility in Saudi Arabia, relied on an aging power distribution system, and the job had to be completed within just 72 hours—day and night, without pause.

Project Background & Urgency: Why This Replacement Was Critical

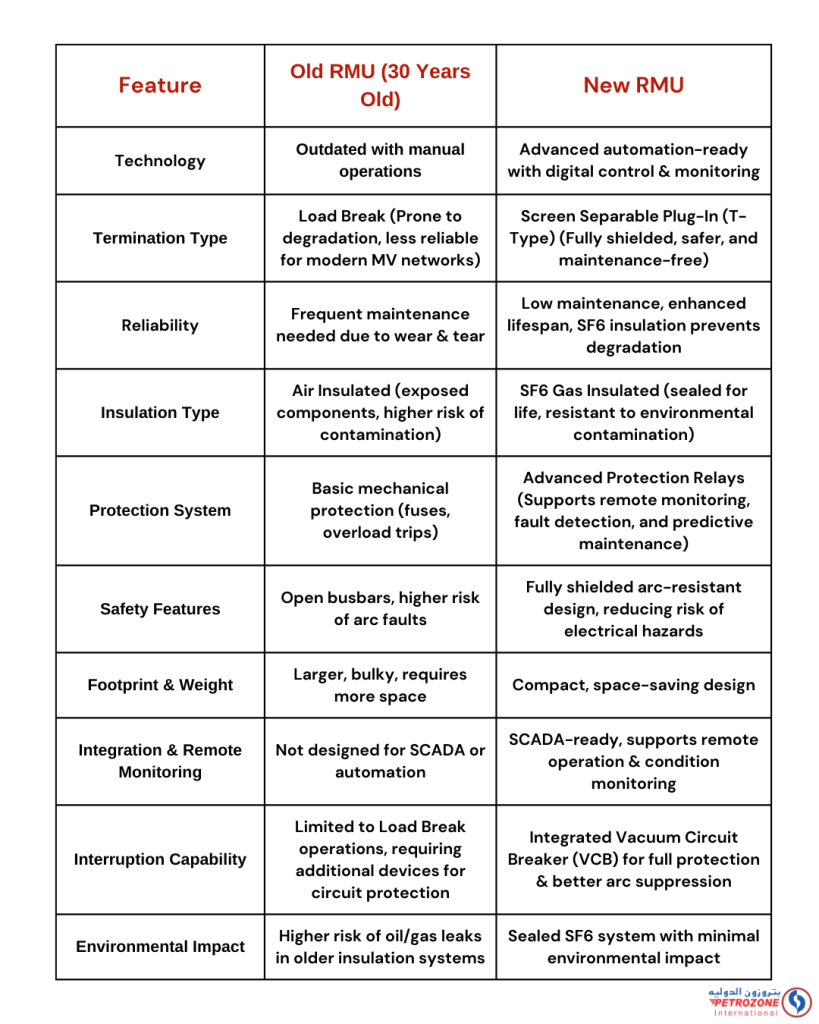

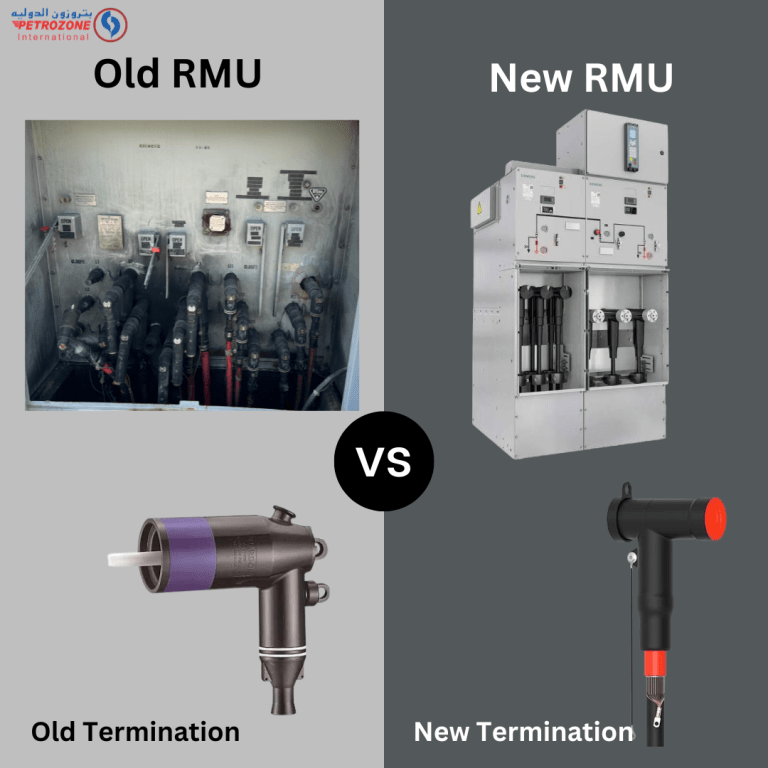

The existing RMUs had been in service for over 30 years, and their aging infrastructure posed a significant risk of failure. Frequent maintenance issues, load break termination failures, and the potential for unplanned power outages made immediate replacement a necessity. Given that this facility was a high-priority operational site, any extended downtime could lead to severe operational disruptions and financial losses.

Our client needed a reliable, modern power distribution solution that could enhance safety, reduce maintenance costs, and ensure system stability for years to come. That’s where Petrozone stepped in.

Old RMU

Project Scope: Precision Execution Under Time Constraints

- Removing 30 existing dead break terminations

- Dismantling the old RMUs

- Preparing the site and laying a new civil foundation

- Installing two new Siemens 33kV 8DJH36 RMUs

- Laying new power cables ranging from 500 sqmm to 70 sqmm

- Performing over 30 new terminations using screen separable plug-in T-type terminations

- Executing 18 cable joints

- Final testing, commissioning, and system energization

With such a critical job, there was no margin for error.

Pre-Shutdown Preparations: Setting the Stage for Success

Before the shutdown, our team carried out extensive pre-installation work to ensure the new RMUs would be installed and energized without delay. This included:

- Site survey and inspection to assess the existing conditions.

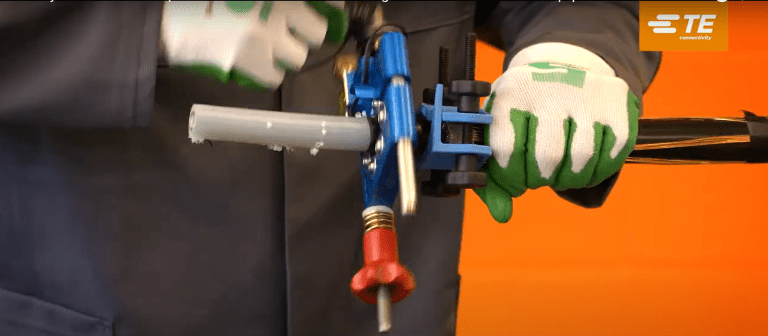

- Cable preparation—removing the outer sheath and insulation screen, ensuring the cables were ready for termination.

- Comprehensive testing of the new RMUs, covering protection relay testing, CT testing, VT testing, breaker testing, and scheme verification.

By completing these steps ahead of schedule, we ensured the actual shutdown process would be efficient and well-organized.

MV Cable Outer Sheath Removal

Shutdown Execution: Phase 1

The moment the shutdown commenced, two teams worked in parallel to maximize efficiency and ensure completion within the tight 72-hour timeframe:

🔹 Team 1 focused on RMU removal and installation

🔹 Team 2 was responsible for cable termination and splicing

The first major task was the removal of the existing load break terminations from the aged RMUs. Given their age and wear, careful handling was required to avoid any damage to the existing power cables. Once all terminations were removed, the old RMUs were dismantled and taken off-site.

At the same time, our civil works team immediately began preparing a solid foundation for the new RMUs. Since the new Siemens 36kV 8DJH36 RMUs had different structural and mounting requirements, the foundation had to be precisely constructed to ensure a secure and stable installation.

Load Break Termination Removal

Shutdown Execution: Phase 2

With the foundation ready, the installation of the new RMUs began seamlessly. Precision alignment and secure mounting were key to ensuring smooth commissioning later in the process.

While Team 1 was handling RMU installation, Team 2 was simultaneously engaged in laying new power cables. This involved:

✔ Pulling and positioning new cables to match the upgraded RMU layout

✔ Performing screen separable plug-in T-type terminations, known for their enhanced reliability and ease of maintenance

✔ Executing 30 terminations and 18 cable joints to connect the new RMU to the distribution network

This parallel execution approach ensured that the shutdown remained on schedule, allowing for an efficient transition to final testing and system energization.

Screen Separable Plug-in T-type Terminations

Final Testing & System Energization: The Moment of Truth

With the RMU installation and terminations completed, the final phase of the project was all about ensuring everything was set for a safe and successful energization. Prior to installation, our team had already performed all critical tests to verify system integrity. Now, in the final stage, only the necessary pre-energization checks were carried out on the RMUs and cables to confirm readiness.

Everything led up to the big moment—the energization. The anticipation was high as the team ran through the final procedures. The system was gradually brought online, and with a controlled sequence, the RMUs were successfully energized, restoring power to the critical facility.

A smooth, flawless energization is always the true measure of a well-executed project, and this was no exception. The satisfaction of seeing the system power up without a hitch was the reward for 72 hours of non-stop precision work.

Siemens 33kV Smart 5 Way RMU

Fasting, Fieldwork, and Iftar: A Ramadan to Remember

This project was executed during Ramadan, a period where our team was fasting while working long hours in the field. Despite this, every engineer, technician, and support staff remained dedicated to the mission.

One of the most memorable aspects was the incredible support from our client. Every evening at Iftar, all work paused, and the client arranged a feast for the team. It was a true testament to teamwork and mutual respect, reinforcing the spirit of collaboration in the face of tough conditions.

Why This Upgrade Was Critical: Old vs. New RMUs

Client Appreciation & The Petrozone Commitment

“Petrozone’s ability to execute such a complex shutdown project in just 72 hours was truly impressive. The team worked tirelessly, and their commitment to quality and safety was evident in every step. We couldn’t have asked for a better execution.” – Client Representative

Why Choose Petrozone for RMU Installation & Cable Termination ?

- Proven expertise in testing & commissioning, RMU installation, and cable termination

- Skilled team capable of handling high-stakes shutdown jobs

- Trusted by industries across Saudi Arabia

- Efficient execution with minimal disruption and maximum reliability

If your facility needs a power upgrade, testing, or termination services, Petrozone International is your trusted partner.

Related Links & Further Reading

Looking to explore more about our services and expertise? Check out the following pages:

🔗 Cable Termination Services – Discover how we handle MV cable terminations with precision and reliability.

🔗 Erection & Installation – Learn more about our process for safely installing electrical equipment and infrastructure.

🔗 Testing & Commissioning – Explore our comprehensive testing protocols that ensure safe energization.

🔗 Contact Us – Got a similar project? Reach out to us today and let’s get it done, the Petrozone way.